With 15,000 new products entering the market each year, the food industry is one of the most competitive markets to enter. Unfortunately, two out of three newly-introduced products fail to succeed in the longer term.

The primary reason for such failures is a subpar food product development strategy.

From the types of products being created to the development process itself, the direction of food product development has changed a lot since the pandemic. The barrier to entry has become relatively low, but it is more challenging than ever to produce a product that sells.

Product development is a crucial element of a brand’s operations and marketing. Understanding the process behind developing, introducing, and marketing a new product to your target audience is essential.

In this guide, we outline the steps involved in food product development, spanning everything you need to know to undertake a successful product development project for the upcoming year.

We examine popular market trends in food product development and mine for what innovative strategies have emerged in recent years.

What Is Food Product Development?

Product development is the complex process needed to introduce a new or improved product to the market. In the food industry, this involves developing food products that interest the target market and address gaps in their current preferences and needs.

Product development is completed in multiple stages and requires input from various teams, from R&D to marketing.

The exact steps of the process, the teams involved, and the time it takes to complete depend on the type of product development you’re undertaking.

Types of Food Product Development

1. Brand New Products

A brand new product is entirely new to the market or the company manufacturing it. It’s become increasingly difficult to come up with food products that don’t already exist, let alone create one that consumers will actually adopt in the long run.

Most food product development centers on refining, iterating, and improving existing items to open up new avenues in terms of audience and marketing.

2. Line Extensions

Extending the product line involves adding more varieties to an already established and successful product category.

Some successful examples include Diet Coke and other variations (Coca-Cola), Colgate Calming Clean (Colgate products with hemp seed oil for soothing), and high-rise, mid-rise, carpenter jeans, etc. (Levi’s).

3. Improved (Existing) Products

Product development is also essential to improve upon existing products’ features or deliverables. The “new” products provide better performance or increase the perceived value of the existing product.

A good example is General Mills’ GMO-free Cheerios.

4. Product Repositioning

Product repositioning involves changing consumer perception of an existing product, such as its image and tangible or intangible elements. This is influenced by and mainly focuses on competitors’ positioning of similar products.

A good example is Coca-Cola’s repositioning of its Mother Energy drink in Australia.

Who Are Involved?

Product development food requires the expertise of and input from various teams in the manufacturing company:

Product Development

The main group in charge of handling the process from start to finish is the product development team. Their duties involve:

- Product formulation

- Nutritional evaluation

- Process testing

- Shelf life testing

- Determining sensory attributes

- Evaluating food safety concerns

- Costing

- And more.

Engineering and Production

Your engineering and production team plays a significant role in laying the groundwork for the production process. They will also contribute to the discussion of the feasibility of the project.

Their tasks typically involve:

- Equipment design and maintenance

- Process controls

- Packaging design

- Employee training

- Sanitation

- Shelf life

- Handling

- Production costs

Purchasing

The purchasing team’s responsibility is to study and research potential vendors to source the ingredients you need. Some of their most important responsibilities include comparing supplier offers, negotiating contracts and pricing, tracking orders, ensuring timely and consistent delivery, reviewing the quality of products, and more.

Quality

The quality assurance team must ensure consumer expectations regarding qualities and sensory attributes are being met. It is done using the following food safety tests:

- Hazard Analysis Critical Control Point (HACCP) preventive controls and prerequisite programs

- Foreign material testing

- Incoming ingredient and packaging safety checks

- Process checks

- Microbiology testing

Regulatory

The regulatory team is mainly involved in the prototyping and processing stages. They work towards ensuring the product is legal, safe, and follows regulations for:

- Product names

- Product codes

- Nutrition labeling

- Standard of identity

Marketing and Sales

The marketing and sales teams are involved in various stages of product development and assigned tasks such as:

- Determining target market and positioning

- Confirming demand

- Product name ideation

- Developing an advertising strategy

- Monitoring competitor sales and product launches

- Product packaging

- And more.

Upper Management

Those in senior management roles must oversee and guide the strategizing process involved in developing a new food product. They can limit their involvement to the decision-making processes or assume a more hands-on role based on the organization’s priority and type of product in development.

Timeline

Food product development timelines can range from several months to years, depending on the product and the complexity of the processes involved.

Brand new products take much longer to develop than line extensions and improvements, which can only take a few months. The development stages are significantly compressed for existing products with established audiences.

Stages of New Food Product Development

Developing a new product takes a lot of time, capital, and resources. It is crucial to divide the process into distinct stages and formulate a detailed plan to keep teams on the same page and set your enterprise up for success.

Every step also comes with checks and balances to ensure the development process is on the right track. If your team encounters an obstacle, it must be dealt with or discarded immediately.

Step 1: Ideation

This stage involves researching product ideas and evaluating them based on feasibility, production costs, potential audience interest, etc.

Market Research

Ideation is also the stage wherein a company will conduct market research to gather data regarding:

- Target market and demand

- Geographical analysis

- Pricing analysis

- Competitive analysis

- SWOT (strengths, weaknesses, opportunities, and threats) analysis

- Consumer testing and feedback

- Feasibility study

- Business regulations and legality analysis

- Product research

- Industry trends

After narrowing down your list of ideas, you can proceed to the next stage.

Step 2: Prototyping/Test Marketing

Also known as the formulation stage, this involves procuring the ingredients, producing the shortlisted products in small batches, and market testing them.

This will help you identify audience interest in the product and gather data you can use for future marketing endeavors.

The market test should tell you which products show a good buyer response to continue the development process. You can pick the top performers from the trial products and move on to the next step.

This stage will bring to light any issues with the following:

- Ingredient sourcing and costs

- Potential shelf life

- Large-scale production possibility

- Patent and copyright infringement issues

Step 3: Processing

Processing involves scaling production to get an idea of incurred expenses. This stage mainly tests the ability of the manufacturer to produce the product efficiently and consistently.

Product changes, specification finalization, food safety, and quality testing are often conducted during this stage.

The final step in processing involves testing the product’s shelf life to ensure it will last long enough to go from production to shipping into the hands of consumers and in their pantries.

You can check the efficiency of each product’s processing by looking at changes in product attributes:

- Sensory attributes

- Shelf life

- Overall functionality

- Nutritional profile

- Product specifications

Step 4: Commercialization

The commercialization phase involves getting the product ready for launch and onto shelves. It includes the following processes:

- Costing finalization

- Additional consumer sensory testing

- Packaging design

- Label creation (logo, nutrition, facts, etc.)

- Highlighting attributes

- Strategizing marketing messaging

- Product positioning

- Effect of distribution on the quality

The commercialization stage is also an opportunity for manufacturers to evaluate drawbacks and negative feedback about the product.

Feedback

Upon launch, the manufacturer is tasked with determining the success of the product using consumer feedback and metrics like:

- Sales revenue

- Market share

- Market interest

- Sales growth

Challenges of Food Product Development

Production Limitations

The most common problem you’ll encounter in the initial stages of the food development process is limitations regarding equipment and processing.

Resolving this might mean a larger investment from the company, such as purchasing new equipment or introducing new processing mechanisms. This might not be feasible for small enterprises with limited resources.

Ingredient Sourcing and Costs

Sourcing the ingredients and calculating costs are crucial in determining the future profitability of the product.

Problems Encountered During Processing

After undergoing the production and processing phases, products may develop unfavorable characteristics. The shelf life might turn out to be too short, or initial marketing tests might not turn out positive.

These issues during processing can lead to a negative outcome that stalls development and extends the timeline.

Teamwork and Communication Hurdles

Due to each department’s different areas of expertise, communication among team members can be challenging.

The safety team’s goals might clash with those of the cost management team, or marketing endeavors may interfere with regulatory guidelines. These issues can be difficult to iron out if the enterprise is on a time or budget crunch.

Food Product Development: Latest Trends and Innovations

Despite the lengthy process and challenges that must be faced, food companies continuously find opportunities to release new products even in over-saturated markets.

Here are the latest trends and innovations you want to take a look at before beginning the food product development process:

-

Alternative Proteins

One of the most popular trends in the food tech industry revolves around the rising consumer demand for alternative protein sources, such as:

- Plant-based nutrition

- Cultured meat

- Lab-grown meat

- Edible insects

- Mycoprotein

- And more.

The driving forces behind the trend are environmental concerns and health issues. It requires protein sources that provide the necessary nutrition while reducing carbon footprint and avoiding harmful ingredients.

-

Nutraceuticals

The nutraceutical trend demands a functional food product that can be used as a nutritional alternative and medicine. It leads to products like:

- Nutritional supplements

- Functional foods

- Medicinal foods

- Gut microbiome-enhancing foods (prebiotics, probiotics, and postbiotics)

- Antioxidant vitamins

- Dietary fiber

-

eCommerce

The eCommerce trend grew exponentially due to the pandemic. Restaurants that continued delivering food through online platforms saw their delivery revenue increase throughout 2020. The best food-related examples are the introduction of ghost kitchens and online food delivery services.

Ghost kitchens or virtual kitchens are places consumers can order from that don’t operate out of a restaurant. These kitchens create food for off-premise consumption only.

-

Food Safety and Transparency

The increasing number of large-scale food recalls has increased the demand for more transparent manufacturing and supply processes.

Consumers are also becoming increasingly aware of the importance of nutritional labels and understanding food grading systems.

Overall, the movement has led to technology like real-time food monitoring coming to the fore.

-

Personalized Nutrition

The demand for personalized food products that cater to consumers’ unique beliefs, dietary requirements, and lifestyle is on the rise.

The solution? Personalized nutrition.

One example that satisfies the higher demand and need for personalized nutrition is 3D food printing. This technology allows restaurants to serve food with customized ingredients according to the consumer’s requirements.

Some popular products to explore in personalized nutrition include:

- Plant-based meat

- Sugar-free items

- Gluten-free

- Vegan-friendly

- Clean Label food products

- And more.

-

Robotic Technology

Automation is the key to solving a majority of troubles in the food industry. It can significantly reduce waste, enhance traceability, improve quality control, improve productivity, and increase food safety.

It also helps solve the labor shortage problem while offsetting high operational costs.

Applications of robotics in the food industry are plenty. Some of them include the following:

- Autonomous drones and delivery vehicles

- Agricultural fruit-picking robots

- Food-handling robotic arms

- Robotic Chefs to automate food production and cooking

- Palletizing robots

- Burger-flipping robotic arms

- Automated harvesting tractors

- Barcode reading computer vision systems

- Robot cleaners

- Packaging robots

- And more.

-

Food Waste Reduction

Food waste not only involves the waste of consumables but also resources like labor, time, and capital. It also increases operational costs and creates a larger carbon footprint.

New strategies being implemented in food waste reduction include:

- Upcycling or reusing food waste

- Food monitoring

- Donating unsold surplus to charities

- And more.

-

Sustainability

Modern consumers are very interested in the impact of their consumption habits on the environment. They’re more inclined to support food products that reduce their carbon footprint.

-

Real and Local

Consumers increasingly demand a food experience that enhances the emotional and sensory elements. This is leveraged by trends like local food sourcing.

Regional food sourcing also offsets supply chain issues and other concerns from the pandemic.

-

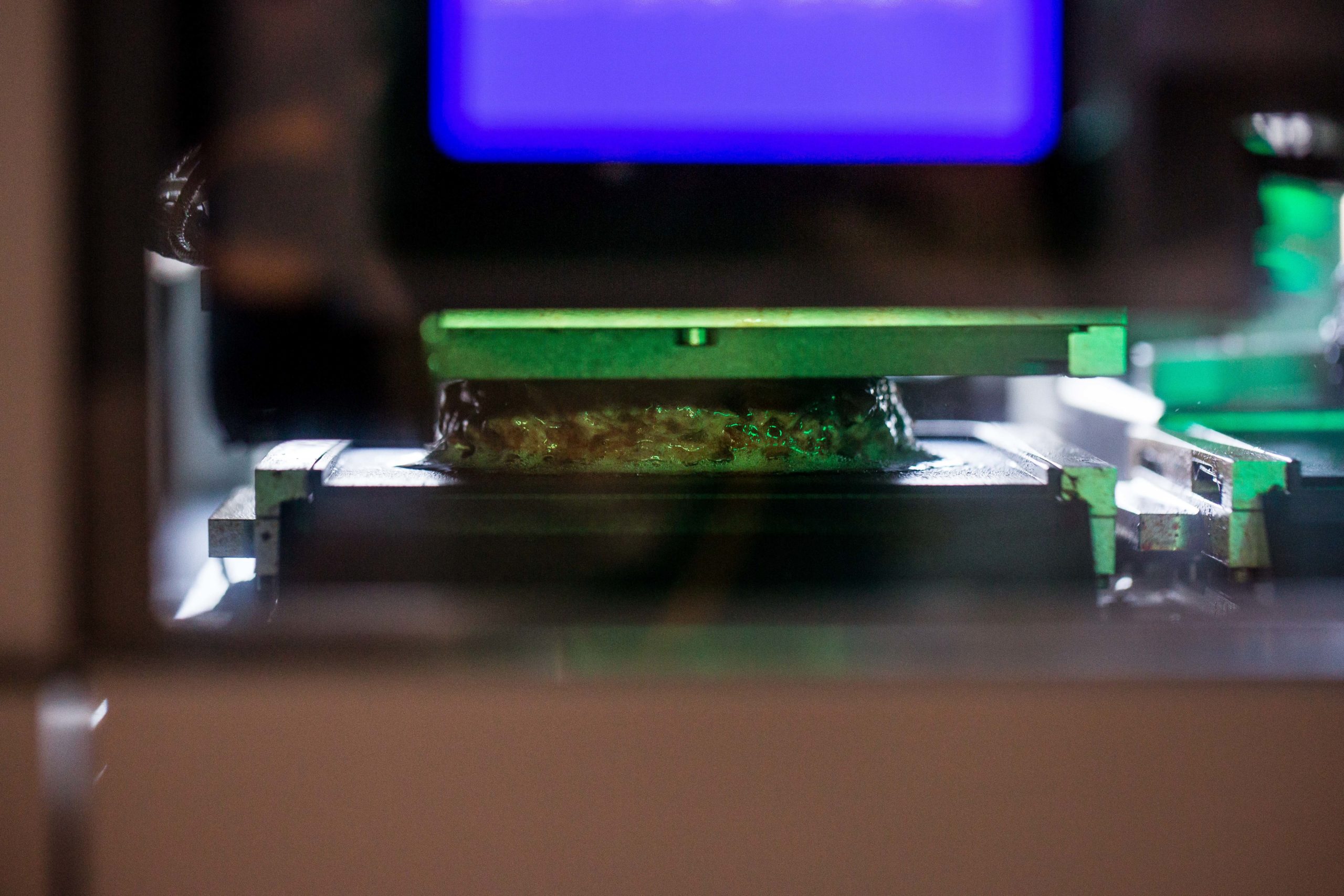

3D Food Printing

3D food printing is a revolutionary trend in food manufacturing. It involves heating edible ingredients and printing them on a plate layer by layer.

The growth of this field is currently restricted by the food products available for extrusion and equipment costs. In the near future, 3D printing will be a suitable solution for personalized nutrition solutions, lower operational costs, and accessible meals created from a sustainable process.

-

Restaurant Digitization

Restaurants are embracing digitization to streamline all elements of their operations. This boosts efficiency, reduces labor costs, minimizes errors, and enables data collection on consumer behavior for data-driven decision-making.

Applications include:

- Self-service kiosks

- QR-based digital menus

- Cashless payment methods

- Voice assistants and chatbots

- Digital inventory management platforms

- And more.

After the pandemic, the demand for the digitization of public spaces like restaurants has only multiplied. One study reveals the total ratio of consumers who prefer ordering digitally on-premises at a Quick Service Restaurant went up to 64% post-COVID-19. In just one year, the growth of customers that prefer to order from ghost kitchens jumped by 20%.

-

Digital Food Management

Digital food management focuses on the following:

- Optimizing manufacturing processes

- Supply chain operations

- Marketing strategies

- Demand forecasting

- Overview of emerging technologies and startups

- Food condition monitoring sensors/digital food fingerprinting

- AI-driven consumer insights

- And more.

-

Fair Trade

Global societal issues are no longer niche discussions—regular consumers have made them their concern, too. And businesses are quickly capitalizing on the fair trade trend.

It focuses on the following issues:

- International development

- Social justice

- Environmental sustainability

- Equitable economic returns

The fair trade trend is most visible in the global sourcing of products like coffee, cocoa, vanilla, sugar, cosmetics, herbs, spices, tea, etc.

Examples of Food Development

Here are some examples of food startups employing the trends mentioned above in their business operations.

SavorEat – 3D Food Printing

SavorEat offers a one-stop meat processing solution that incorporates automation, plant-based alternatives, and personalization. The cutting-edge solution offers a customizable meat alternative while lowering environmental impact and food waste and making the food on-demand.

Bear Robotics – Robotics

Bear Robotics’ autonomous serving robots bus tables and deliver meals and drinks to customers. These solutions significantly reduce the strain on staff from labor shortages and high customer demand.

Food Drop – Food Waste Reduction

Food Drop is a British startup dedicated to reducing food waste. They connect local retailers and food suppliers with charities and organizations that help feed those in need.

Qualizy – Food Safety and Transparency

Qualizy provides software solutions to automate food safety compliance without paperwork. Their software enables users to:

- Deploy digital food safety and health and safety management systems

- Monitor temperature

- Track allergens and expiry dates

- Deploy audits and checklists

- And more.

NGX – Personalized Nutrition

British startup NGX offers personalized meal-shakes created by nutritionists. Their shakes are packed with all necessary nutrients in daily measurements and custom-made for each customer.

Orderscape – ecommerce

Orderscape is a voice-assisted service that enables customers to search for nearby restaurants, browse menus, and place orders.

Farmhand Organics – Nutraceuticals

Farmhand Fermented Foods offers probiotic farm-to-fork solutions to consumers looking for alternative nutrition. Their product offerings include brands of living, raw, organic krauts, and kimchi.

Food Market Hub – Digital Food Management

Based in Malaysia, Food Market Hub is revolutionizing digital food management using cloud technology. Their startup offers cloud-based solutions to digitize inventory management, procurement, and all backend operations.

AAHI – Restaurant Digitization

AAHI is a Czech startup offering restaurant digitization solutions. Their products allow restaurants to deliver digitized and contactless interactive services to consumers using:

- Digital menus

- QR-based ordering

- Contactless payment methods

- Feedback tools

- Sales analytics

- And more.

The Protein Brewery – Alternative Proteins

The Protein Brewery’s FERMOTEIN is a protein alternative that’s grown cruelty-free in the lab. The food product has a meat-like taste and is made by brewing non-allergenic crops and fungi with essential amino acids and fiber.

Tastewise – Digital Food Management

An Israeli startup Tastewise is changing the way restaurants collect and use data to understand consumer behavior.

Their food intelligence products gather data from social media interactions and digital restaurant platforms to help restaurants with the following:

- Prioritize ingredients

- Identify trending dishes

- Retain customers

- Improve marketing strategies

- Try product innovations

- And more.

ThisFish – Seafood Traceability

Tally, a software solution from Canadian food startup ThisFish, offers consumers real-time actionable data. Their software solutions use AI and machine learning to:

- Automate tasks

- Collect data

- Enable live dashboard monitoring

- Run predictive analytics

- Digitize workflows

- And more.

Voll Sante – Nutraceuticals

Voll Sante is an Indian functional food and nutraceutical startup offering nutritious and medicinal food that is also natural, convenient, and tasty. Their offerings cater to consumers seeking:

- Protein supplements

- Bone health

- Immunity support

- Infection control

- And more.

Lumitics – Food Waste Reduction

Insight is a food waste tracker from Singapore-based startup Lumitics. It helps reduce restaurant waste by tracking the food waste from the kitchen. Their tracker optimizes:

- Food production based on buffet lines

- Trimmings

- Purchasing

- Menu deliverables based on consumer preferences

- And more.

ento – Alternative Proteins

A startup from Malaysia, ento, offers a sustainable source of protein made using insects like cricket.

Conclusion and Looking Ahead

Food product development is an important driver of growth in the global food industry. It provides consumers with new and improved product solutions while catering to the population’s ever-evolving preferences and needs.

Product development in food also allows restaurants, manufacturers, and retailers to reduce operational costs through creative solutions.

However, a large percentage of products fail shortly after launch. This necessitates adopting a complete and detailed product development strategy, sound research, and a complete understanding of the latest trends and innovations in the industry.

Regardless of the method chosen and the success rate, food product development allows market players to engage in healthy competition that improves the industry’s standards.